Designatronics is hosting a sales meeting.

Put this on your calendar – Tuesday, June 6, 2017

See how we are already realizing the benefits of being in one location allowing for better

process control and increased efficiency and capacity.

Learn what we are doing to better serve our customers.

Don’t miss this opportunity to tour our brand new facility, exchange ideas and share your thoughts on what we can improve.

While the formal program is Tuesday, June 6th; Reps are invited to join us at our facility

Monday and Wednesday to spend time with Engineering, Customer Service and Operations.

Hotel rooms have been blocked.

Designatronics is on the Move!!!! 3/1/2017

The move is complete to 250 Duffy Avenue, Hicksville, NY

The much anticipated move occurred last week. We have all settled into our new surroundings and are ready to tackle any unresolved issues. Our customer service team is here to help! We are working hard to maintain the high-level of quality in our products and services you have grown to trust, and appreciate your ongoing support. We are proud of our people and our new “HOME” and look forward to visitors later this year.

The much anticipated move occurred last week. We have all settled into our new surroundings and are ready to tackle any unresolved issues. Our customer service team is here to help! We are working hard to maintain the high-level of quality in our products and services you have grown to trust, and appreciate your ongoing support. We are proud of our people and our new “HOME” and look forward to visitors later this year.

Trade Shows

MD&M West 2017 was very successful for us this year. Over 150 leads were gathered and distributed for follow up with the hopes of new or repeat business. This year we saw better booth traffic than the previous two years and as a result booked the same space for MD&M West 2018.

Design 2 Part, Grapevine TX – We had to cancel our participation at this show due to the move but look forward to its being part of the show schedule for next year.

On the schedule for the remainder of the year are:

Design 2 Part, Schaumburg, IL – May 10 & 11, 2017

Design 2 Part, Santa Clara, CA – May 24 & 25, 2017

ATX East, New York, NY – June 13, 14 & 15, 2017

Design 2 Part, Marlborough, MA – Sept. 27 & 28, 2017

A small portion of the manufacturing area in the new facility.

Firecomms Appoints Field Applications Manager to Support Growing Americas Market

Firecomms, a global leader in the optical component industry, is pleased to announce the appointment of Dylan Loughnan as the company’s new Field Applications Engineering Manager for the Americas.

As the company’s primary technical resource for the growing Americas market, Loughnan will support customers in the development of fiber optic solutions. The company’s customers — from a wide variety of markets including industrial automation, transportation, medical imaging, renewable energy and home networking — will benefit from his expertise with the company’s portfolio of fiber optic transceivers and related solutions.

“As a senior member of the engineering and technical staff, Dylan has been involved in all aspects of the development of Firecomms product roadmap as well as providing advanced technical support to our customers,” says Lawrence Thorne, Firecomms’ Vice President of Sales & Marketing, The Americas. “Having a strong technical resource close at hand will benefit our customers in this region.”

Loughnan, based in Boston, has been with Firecomms for over four years, most recently as a Sr. Product Design Engineer. He has an advanced physics degree from Cork Institute of Technology (CIT) with graduate research experience at Massachusetts Institute of Technology (MIT).

About Firecomms Ltd.

Firecomms, a global leader in the provision of fiber optic solutions and optical transceivers, skilfully combines state-of-the-art compound and silicon semiconductor technology with inventive small-scale integration to develop products that drive communications networks in power and energy, industrial, transportation, medical and consumer markets.

Firecomms is jointly headquartered in Cork, Ireland and Tongxiang, China with additional facilities in the USA, Shanghai and Southeast Asia. To learn more about how Firecomms can help your business, please visit www.firecomms.com.

Microflex Flexible Cable Harnesses

Our Microflex flat cable technology, designed to meet MIL-DTL-55302F standards, features a flat polyester harness with a screw fixing for high-vibration environments. The Microflex cable harness jumper mates with a CMM 220 connector for high mechanical resistance, with a life expectancy of 10 million cycles.

With up to 60% weight reduction compared to round cables, Microflex harnesses are ideal for unmanned aerial vehicles and other robotics applications where weight is at a premium. Three harness versions are available – female-female, solderpin-female and octopus multi-branch – with up to 60 2mm contacts per connector.

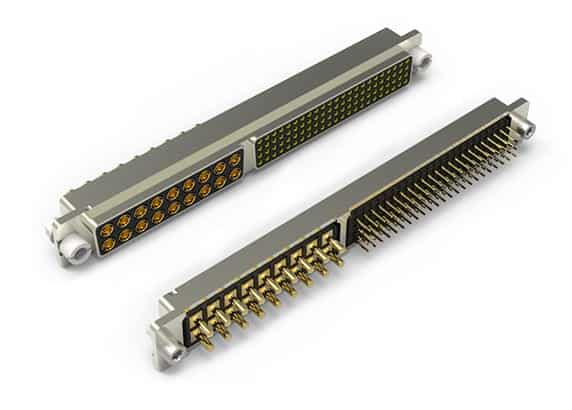

DMM Micro-D Mix Connectors

Our DMM Micro-D Mix connectors are compatible with MIL-DTL-83513G standards and offer a more flexible choice of arrangements to traditional Micro-D or Sub-D connectors, with more than two million possible configurations. Each connector can mix signal, power and coaxial contacts in up to four rows, encased in either a one-piece or split two-piece backshell.

DMM Micro-D Mix connectors can be used for board-to-board, board-to-wire, wire-to-wire or panel mount arrangements, and are constructed from a PPS insulator in an aluminum alloy 6061 shell that can withstand harsh environments and temperatures from -55 °C to 125 °C.

CMM Micro Connectors

Our CMM Micro Connectors have been designed to meet or exceed the electrical and mechanical performance criteria of MIL-DTL-55302F and BS-9525-F0033 standards.

Three kinds of 2mm contact – high power, high frequency and low frequency – can be combined in up to three rows, allowing for more than 20 million possible standard arrangements. This high level of modularity provides customers with flexible design options and makes the CMM Micro Connectors especially suited for space and weight-contained applications such as unmanned aircraft.

CMM connectors can be used for board-to-board, board-to-wire or wire-to-wire arrangements, with contacts on either the PCB or the cable.

OMM Circular Micro Connectors

Our OMM circular micro connectors are designed for board-to-cable interconnection in restricted-space applications such as unmanned vehicles, with a compact modular design featuring up to eight contacts that results in up to 50% weight and space saving compared to our standard CMM 220 connector.

Manufactured from oxygen-free PPS material, the connectors are highly resistant to solvents, radiation and humidity. Signal terminations are available in pre-wired, SMT or straight tail configurations, and in addition to the standard 8 position housing, 6- and 10-position custom options are available upon request.

Custom Solutions

As the unmanned industry develops and changes, you need new products that meet specific requirements and constraints. Our Custom Solutions department offers the services and interconnect solutions you require, such as the retrofit of obsolete products, standard product modifications and new designs.

Our dedicated team of engineers will work with you to develop new solutions to reach your specific design goals. You will find our staff to be flexible and reactive, offering superior quality control and technical support. We will work with you to conduct a feasibility study and to develop small- and medium-series prototypes.

Experience

- Worldwide customers: over 60 projects per year

- EN 9100 processes for risk assessment and traceability

- A diversified customer base including unmanned defense, aeronautics, medical, and energy

Customer Satisfaction

- Design a unique solution to solve customer challenges

- Reactivity in each step from design to manufacturing

- Fully integrated manufacturing for 100% quality control and scheduling flexibility

Nicomatic press release

DMM backshell-The EMI fighter

The multiplication of data in electronic systems could have disastrous results if the impact of the cross talk was not anticipated. Under an electromagnetic perturbation (EMI, RFI or EMP), the cable’s conductor acts as antennas and picks up the radiated signals. The reception of this interference surely impacts the initial signal integrity.

Nowadays, data rate is exponentially increasing and high-speed protocols are omnipresent. A proper shielding appears as a key part of the design. The most efficient shielding method is to enclose the cable in a metal braid which is then grounded to one or both ends of the cable thanks to the network nodes: The connectors and backshells.

Backshell as a rear part of NICOMATIC connector DMM MIL-DTL-83513G is used to secure the cable and to avoid stresses on the soldered/crimped part of the contact. It also shields against electrical interference (EMI/RFI protection) with Transfer Impedance (Zt) under 200mOhm from10 KHz to 400Mhz. Made of Aluminium 6061 with chemical nickel finishing, it protects from mechanical damages.

Back chimneys are designed in a shape of an ellipse, fully compatible with Band-it type system. Bands and clamping hand tools are available on our website. Openings allow to fasten the wires with a Serflex system and also to ground the shielding of twisted pair cable.

There are 2 available designs of our backshells, split and mono.

The split backshell presented in the video is fully compatible with all Nicomatic DMM connectors, and designed as a two-piece shell. Fixing hardware is mounted on the connector and the locking of the two parts of the shell does not interfere with the harness which is made independently in a previous stage. It results an easy and quick assembly.

Mono backshell is fully compatible with all Nicomatic DMM connectors. Lighter, smaller and cheaper it is a smart and cost effective solution for series stage. Note that fixings are captive and integrated to the backshell.

R&D department has been working hard on the backshell topic, especially How to use the ergonomics to limit risks and save time during the cabling operation. Don’t hesitate to contact customsolution@nicomatic.fr

The DMM range and its backshells are available on our Nicomatic website,DMM tab

***** NEWS *****:The backshell configurator allows in a few clicks to configure and download the expected CAO model, Test it online!

Nicomatic Video

Speak to an Engineer ATX East 2016

Join us June 14-16, 2016 at ATX East in NYC.

Visit our booth, #2524, and see our exciting new products such as our new spherical bearing line. Examples of our precision gears, gear assemblies, and other mechanical components will be on display. Our engineers and product experts will be at the booth to discuss your specific applications. To take advantage of complimentary expo admission, specify the Source Code ‘INVITE’ when registering. We look forward to seeing you at this year’s expo! Phone: Call us at: (516) 328-3300 Email us at: sdp-sisupport@sdp-si.com Visit our website at:sdp-si.com |

HCT 127 Portable Hand Crimp Tool – Nicomatic

Hand tools are generally intended for occasional use and low volume applications. Our HCT-127 hand crimp tool available in 1.27mm pitch has been made to support our customers in the miniaturization process of their sub-assemblies and equipments.

The main reasons to use a 1.27mm pitch tool are numerous. Here are some of them :

– Printed Electronics & commercial applications used in field portable equipments: the operator can easily transport the tool & the contacts to be crimped

– Membrane switches prototypes & small series: there is no need to invest in a bigger equipment to test new opportunities on the markets or test new own developments

– Flat & secure connections in reduced space (robotics, medical device with vibrations etc.) where retention and electrical conductivity specification need to be far more reliable vs. FFC with Z.I.F. / L.I.F. type of connections

Based on the Crimpflex patent, the tool will allow contact crimping by piercing the conductor in 6 points for mechanical retention by 2 points & electrical continuity by 4 points with the lowest possible contact resistance.

Matching housings exist in latched or non-latched versions.

The HTC-127 packaging also features written instructions & 2D drawings will be available for the contacts & the tool itself from end December 2015

ADS General Product Demo Video – Nicomatic

Nicomatic designs and manufactures innovative interconnect solutions with a dedicated product portofolio in connectors & man-machine interface switching technology.

CMM Micro Connectors Video – Nicomatic

MicroFlex Video – Nicomatic

Microflex jumpers fit to all applications where space & weight savings are critical.

This new solution allows a strong mechanical resistance thanks to jackscrew fixing. All types of high vibration environments: medical equipment, aircraft control units, flight entertainment (IFE systems), eletrical power systems, multi functional display units…

Nicomatic Mars expedition

On the 14th of March 2016, the world was following ExoMars blastoff from the Baikonur Cosmodrome in Kazakhstan.

ExoMars is a program led by the European Space Agency (ESA), and Roscosmos, the Russian federal space agency. The main mission is to find life on Mars.

The launch system “Proton” has sent the “TGO”, Trace Gas Orbiter and “Schiaparelli” landing demonstrator on a seven-month journey to Mars.

Upon arrival next October 2016, TGO will begin searching the Martian air for methane (a possible sign of life) from orbit, while Schiaparelli will descend to the surface, to test out landing technologies for the second part of ExoMars a life-hunting rover that’s slated to blast off in 2018.

CMM micro-connectors from Nicomatic have been used for PC board interconnections in the “ACS”, Atmospheric Chemistry Suite, developed by the Space Research Institute of the Russian Academy of Science. ACS is an instrument placed inside TGO space module that enables the detection of water, methane & a variety of other constituents in the atmosphere.

“Our connectors proved to be successful in resolving a problem of weight & space saving in the electronic module” says Tatyana Collomb, Area Sales Manager responsible for the project at Nicomatic. “The oxygen-free insulator of our connectors & a superior reliability of the contact made it possible to perfectly adapt to space conditions”, continues Tatyana.

This isn’t the 1st time Nicomatic connectors are being used in outer space.

After the success of the Jade Rabbit Chinese Space Program, where a specific connector design

had been achieved, a new mission now takes the connectors further into space. A few months ago, Jade Rabbit rover safely landed on the moon in the right place without any damage thanks to the signal transmitted with a Nicomatic connector. Nicomatic has also taken part in a number of satellite projects

MARS – OUR FURTHEST TRIP EVER

Soon in the orbit of Mars

- ESA Exomars robot

ExoMars is a program led by the European Space Agency (ESA), and Roscosmos, the Russian federal space agency. The main mission is to find life on Mars.

The launch system “Proton” has sent the “TGO”, Trace Gas Orbiter and “Schiaparelli” landing demonstrator on a seven-month journey to Mars. Upon arrival next October 2016, TGO will begin searching the Martian air for methane (a possible sign of life) from orbit, while Schiaparelli will descend to the surface, to test out landing technologies for the second part of ExoMars a life-hunting rover that’s slated to blast off in 2018.

CMM micro-connectors from Nicomatic have been used for PC board interconnections in the “ACS”, Atmospheric Chemistry Suite, developed by the Space Research Institute of the Russian Academy of Science. ACS is an instrument placed inside TGO space module that enables the

detection of water, methane & a variety of other constituents in the atmosphere.

“Our connectors proved to be successful in resolving a problem of weight & space saving in the electronic module” says Tatyana Collomb, Area Sales Manager responsible for the project at Nicomatic.

“The oxygen-free insulator of our connectors & a superior reliability of the contact made it possible to perfectly adapt to space conditions” continues Tatyana.

This isn’t the 1st time Nicomatic connectors are being used in outer space.

After the success of the Jade Rabbit Chinese Space Program, where a specific connector design had been achieved, a new mission now takes the connectors further into space. A few months ago, Jade Rabbit rover safely landed on the moon in the right place without any damage thanks to the signal transmitted with a Nicomatic connector. Nicomatic has also taken part in a number of satellite projects.